KwiIshishini lokupakisha, ukuveliswa kunye nokulungiswa kweebhokisi ezikhutshelweyo Beka iimfuno eziphezulu kwi-ton Ukunganyangeki, ubunzima kunye nokubukela izixhobo zokusika. Kwiminyaka edlulileyo, i-tungsten ye-tungsten iye yaba yinto yokhethoI-slitter slitter ye-slitterNgenxa yepropathi yayo efanelekileyo yomzimba kunye nekhemikhali. Kweli nqaku, sijonga le nto yenza ukuba i-carbide ye-tungsten ivele kwindimbane njengolona khetho lubalaseleyo lweempuku ezityumkileyo.

I-tungsten carbide, ekwabizwa ngokuba yi-tungsten carbide, sisixhobo se-Aloble eyenziwe ngenkqubo ye-powdersul. Ine-carbide ye-tungsten kunye ne-cobalt kunye nezinye ii-binders zensimbi, kwaye zinothotho lwezinto ezibalaseleyo ezinjengobunzima obuphakamileyo, ukuxhaphaza okuphezulu, amandla aphezulu kunye nokunganyangeki. Ezi ndawo zenza ukuba iibhloko ze-tungsten carbide zokusika i-blades zigqibelele ekujonganeni neebhokisi ezihlawulisiweyo, ubunzima obukhulu, izinto eziphakamileyo.

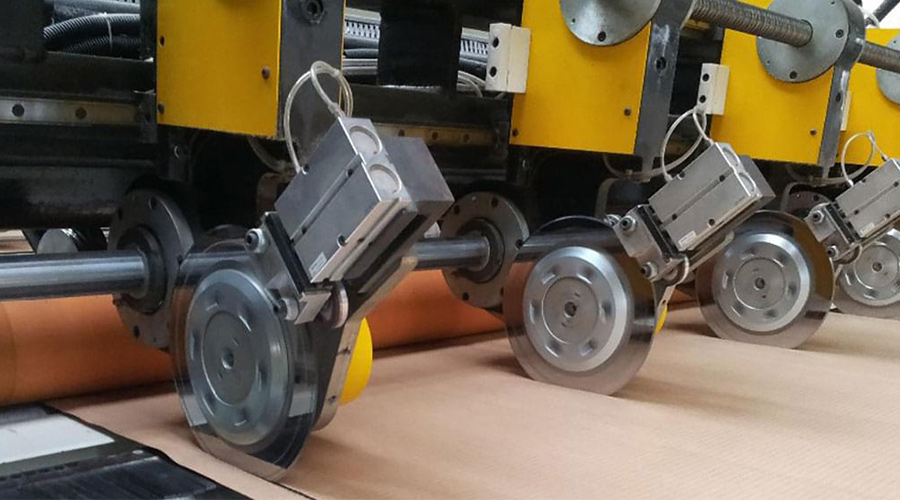

Inkqubo yokusika kweebhokisi ezihlawulelweyo ifuna amabala ngokuxhaphaza kakhulu. Izixhobo ze-tungsten ze-tungsten zinxibe ngcono ukunganyangeki kunezixhobo zemveli ezifana nensimbi yensimbi ephezulu kunye nentsimbi engenasiseko. Oku kuthetha ukuba ii-tungsten ze-tungsten ze-tungsten zinobomi obude, zibangela ixesha lokuphumla elingaphantsi kunye nokunyusa imveliso. Kumzi-mveliso wokupakisha, oku kuthetha iindleko ezisezantsi zokulungisa kunye negalelo eliphezulu.

Ubunzima obuphezulu be-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten inesizathu esiphambili sokuba sesona sixhobo sifanelekileyo sebhokisi echetyiweyo. Ubunzima ngumgangatho wokukwazi kwezixhobo zokuxhathisa ukohlwaya kunye nokuntywila. Ngexesha lokusika kweebhokisi ezihlawulelweyo, ibala kufuneka likwazi ukumelana noxinzelelo oluphezulu kunye noxinzelelo. Ubunzima be-tungsten ye-tungsten iphakame kakhulu kunenye yezinye izinto ezinqumlayo zemveli, ezivumela ukuba zigcine ubukhali bomphetho ixesha elide, qinisekisa umgangatho wokusika.

Ukongeza ekunciphiseni ukunyangwa kunye nobunzima, i-tungsten ye-tungsten ikwanengxaki yokuphumelela. Ngexesha lenkqubo yokusika, iblade ivelisa ubushushu, kwaye ukuba ubushushu bungenakuchithwa ngexesha, kuya kukhokelela ekulahlekelweni kwebala kunye nokudakumba komda. Ukuqhubela kwe-tungsten ye-tungsten kuyanceda ukunciphisa umphumo we-thermal ngexesha lokusika, ukugcina uzinzo lwe-blade kunye nokunqunyulwa kokusika.

Amagqabi e-tungsten ye-tungsten ye-tungsten ikwakwazi ukufezekisa iziphumo ezifanelekileyo kunye nokuzibamba okuchanekileyo kwi-conrougged cuted cute. Oku kubalulekile ukuthintela izinto ukuba zingahlukani phakathi kweengxwaba okanye ukuqhubela phambili kwimiphetho. Ingakumbi kwiTekhnoloji yokusika i-Ultrasonic yokusika, ukusebenza kakuhle kwe-tungsten ye-tungsten ye-tungsten ye-tungsten inikwa umdlalo opheleleyo, ukwandisa ngakumbi ukusebenza kunye nokulungisa umgangatho wokusika.

Ngesishwankathelo, i-tungsten carbide yeyona nto ilungileyoIphepha elitshisiweyo lephepha lokusikaNgenxa yobunzima bayo obuphakamileyo, ukuxhaphaza okuphezulu, amandla aphezulu kunye nokuphumeza okuhle. Ayiphuluki kuphela imveliso kwaye inciphise iindleko zesolo, kodwa ikwaqinisekisa ukuba ukusika umgangatho kunye nokuchaneka. Ngokuphuhliswa okuqhubekayo kwe-Blade yoyilo kunye neSayensi yeZinto ezibonakalayo, ukusetyenziswa kwe-tungsten blades kwishishini elibanzi kuya kuba nekamva elibanzi, ukubonelela ngezisombululo ezingcono zokulungisa nokuchaneka ngokuchanekileyo.

Emva kwexesha, siya kuqhubeka nokuhlaziya ulwazi, kwaye unokufumana ulwazi ngakumbi kwiwebhusayithi yethu (i-Palverntool.com) blog.

Ewe kunjalo, unokunikela ingqalelo kwimidiya yethu yaseburhulumenteni: