I-Slitter Blade yinto ebalulekileyo yeI-Bhs (ibhokisi esenza isantya esiphezulu)umatshini, osetyenziswa kwimveliso yokupakisha ukunciphisa amaphepha ebhodi evuyiweyo ibe bububanzi obunqwenelekayo. Idlala indima ebalulekileyo ekuqinisekiseni ukunqunyulwa nokucutha okusebenzayo, nto leyo ichaphazela ngokuthe ngqo umgangatho kunye nemveliso yenkqubo yokupakisha. Kweli nqaku, siza kuthatha inxaxheba kubaluleke kubabukeli se-slitterBhsoomatshini, iintlobo zabo, kunye nokugcinwa.

Ukunyanzelwa kokungalunganga ukupakishwa okugqibeleleyo

Umsebenzi ophambili wesilayidi se-slitter kwiBhsUmatshini kukusika amaphepha ebhodi ekhutshiweyo ngokuchanekileyo nangokungaguqukiyo kububanzi obufunekayo. Oku kusika ngokuchanekileyo kubalulekile ukwenza izinto zokupakisha ezinjengeebhokisi, iibhokisi, kunye neziqulatho ezinemiphetho, zihambelana ngokungenamthungo, kwaye zibonelela ngokhuseleko olufanelekileyo kumxholo ngaphakathi. Iiblikhi ze-slitter zenzelwe ukwenza ukusikwa okuninzi ngaxeshanye, zivumela imveliso yesantya esiphezulu kunye nokwandisa ukusebenza kwenkqubo yokupakisha.

Iindidi ze-Slitter Blades

Kukho iintlobo ezahlukeneyo ze-slitter blades ezifumanekayoBhsoomatshini, kwaye ukhetho lwe-blade luxhomekeke kwiimfuno ezithile zenkqubo yokupakisha. Ezinye iintlobo eziqhelekileyo zeeblitter ze-slitter zibandakanya:

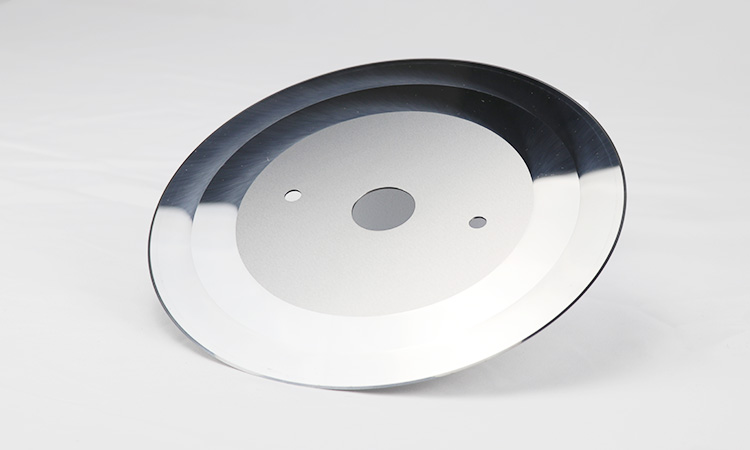

I-Rostter Flitter Blades: La maqhekeza anemilo esijikelezwe kwaye ajikeleze ngexesha lokusika. Baqhele ukusetyenziswa kumaphepha ebhodi enqamlezileyo etyalwe kwiBhsumatshini kwifom yoRhululo eqhubekayo.I-Rostter Flitter Bladeszaziwa ngesantya esiphezulu sokusika kunye nokukwazi ukujongana nemithanga enkulu yezinto.

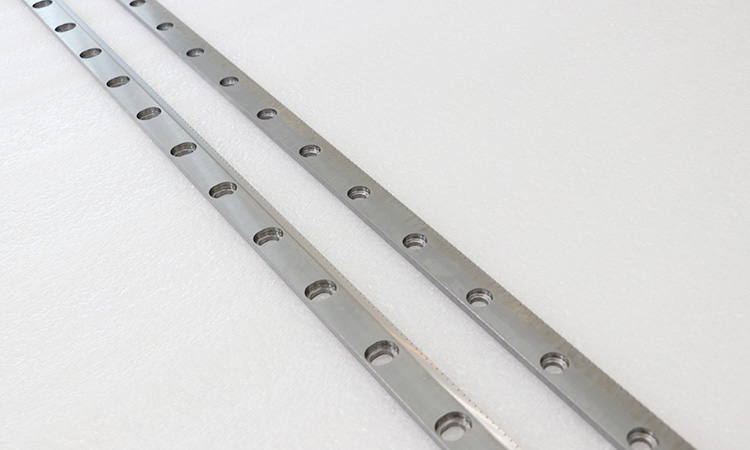

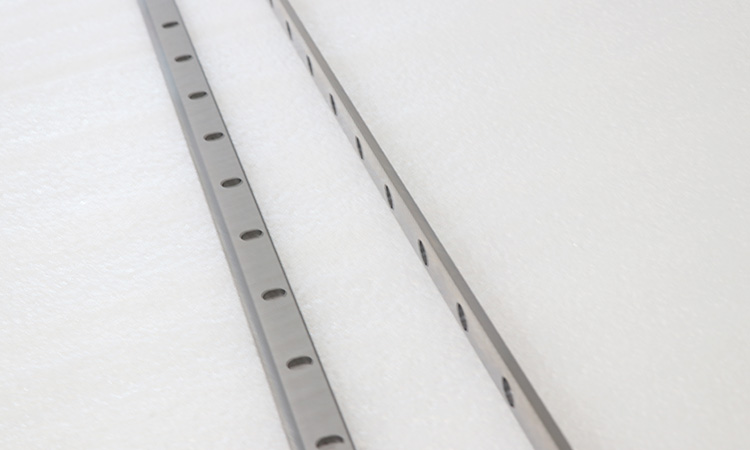

Shear slitter blitter blades: Ezi blade zinemikhono ethe tye, ebukhali kwaye isebenze ngokucheba okanye ukusongela isenzo sokunciphisa iimakhishithi zebhodi. Ziqhelekile ukusika amaphepha aprintiweyo kwangaphambili okanye amashiti anobude obahlukeneyo okanye ububanzi.Shear slitter blitter bladeszaziwa ngokuncitshiswa kwabo okucocekileyo nokuchanekileyo.

Ukulungiswa kwamabala eSlitter

Ukulungiswa ngokufanelekileyo kwamagqabi esilayidi kubalulekile ukuqinisekisa ukuba abantu abade kunye nokusebenza ngokuchanekileyo. Nazi ezinye zeengcebiso eziphambili zolondolozo:

Ukucocwa rhoqo: Amagqabi okutyibilika anokubaqokelela inkunkuma, intsalela entsalela, okanye uthuli olunamanzi ngexesha lenkqubo yokusika, enokuchaphazela ukusebenza kwabo. Ukucocwa rhoqo kwamaqhekeza usebenzisa iindlela ezifanelekileyo zokucoca kunye nezixhobo kubalulekile ukuze ususe nakuphi na ukwakhiwa kunye nokuqinisekisa ukusika okugudileyo.

Ukulolonga okanye ukutshintshwa: Ii-Blades ze-Slitter zinokuba dumbi malunga nexesha elifanelekileyo lokusikwa kweBhodi ePhakathisiweyo. Amabala amdaka anokubangela ukusikeka okumgangatho, ukwanda kwemveliso yemveliso, kunye nokusetyenziswa kwamandla okuphezulu. Ukulola okanye ukutshintsha ama blade njengoko kufuneka kubalulekile ukugcina ubuqaqawuli babo kunye nokusika ukusebenza kakuhle.

Ulungelelwaniso: Ukulungelelaniswa okufanelekileyo kweBlades ze-slitter kubalulekile ukuqinisekisa ukusikwa ngokuchanekileyo. Amagqabi angasebenziyo anokubangela ukusikwa okungalinganiyo okanye kwimiphetho eyonakalisiweyo, echaphazela umgangatho wezinto zokupakisha. Iitsheki zokulungelelanisa rhoqo kunye nohlengahlengiso ziyimfuneko ukugcina ukusika ngokuthe ngqo.

I-Lubritation: Iiblitter zamatywina zinokuxhamla kwi-qubirication ukunciphisa ukuxabana nokunxiba ngexesha lokusika. Ukufaka isicelo esifanelekileyo se-goodricants okanye iingubo ukuya kwi-blades kunokunceda ukwandisa ixesha lazo lokuphila nokuphucula ukusebenza kwabo.

Ukuqukumbela

Amagqabi atyibilikizizinto ezibalulekileyo zeBhsOomatshini abasetyenziswa kwimveliso yokupakisha ukuze batshintshele kwaye bakufaneleke kwi-SHEDREADS. Ukukhetha uhlobo olufanelekileyo lwebala lesilayidi, ulondolozo oluqhelekileyo, kunye nokusetyenziswa okufanelekileyo kubalulekile ukuqinisekisa ukusebenza kakuhle kunye nobomi obude bee blade. Ngokulandela iinkqubo ezifanelekileyo zolondolozo, abavelisi abaphakisiweyo banokuqinisekisa ukuba iiblabhu zazo zesilayidi zihambisa icocekile, ukunqunyulwa ngokuchanekileyo kunye negalelo kwizinto zokupakisha eziphezulu.

IXESHA LOKUQALA: APR-21 ukuya kwi-2123