Kwinqaku lokugqibela sifunde ukuba yintoni itekhnoloji ye-CNC kunye neentlobo kunye nemisebenzi ye-CNC ye-Cnc. Namhlanje, siyaqhubeka nokucacisa ukusetyenziswa kwamabala e-CNC kumashishini ahlukeneyo, izinto ekufuneka ziqwalaselwe xa ukhetha amabala e-CNC kunye nezibonelelo zeI-CNC KAKHUMIL.

Izicelo zosetyenziso lwamabala e-CNC kumashishini ahlukeneyo

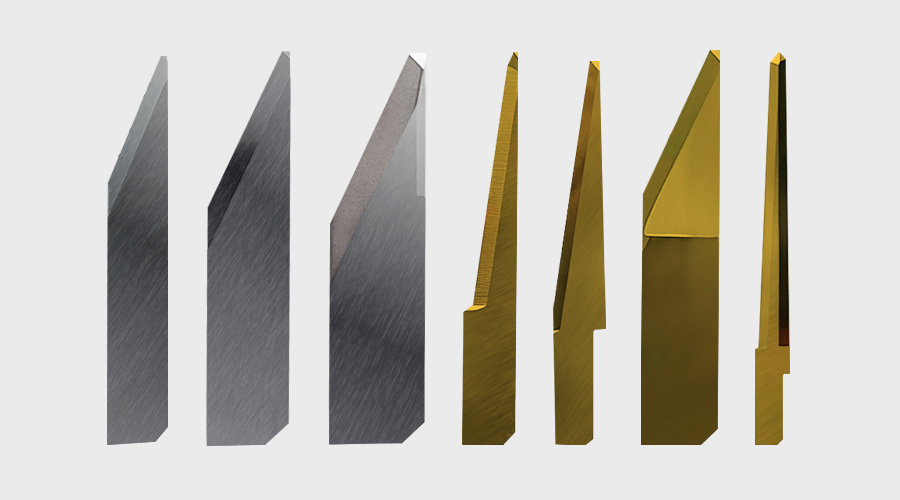

Ukutshintsha kunye nokuchana kwamabala e-CNC kwenza ukuba bazizuze kwizixhobo ezahlukeneyo zemizi-mveliso, apho ukunqunyulwa, ukubekwa, kunye nokuluphethwa ziinkqubo ezibalulekileyo. Kushishino lweenkuni, ii-CNCK ze-CNAKS zisetyenziselwa ukusika izinto zenkuni ukwenza ifanitshala yenkuni ukwenza ifanitshala yenkuni ukwenza ifanitshala yenkuni, iKhabhinethi kunye nezinto zokuhombisa. Ukukwazi ukufezekisa uyilo oluntsonkothileyo kunye nokugcoba okugudileyo kwenza ukuba i-CNC Khumbuli ye-Blades iyathandwa phakathi kweenkuni ezifuna ubugcisa obukhulu kunye nokuchaneka.

Kwimiqondiso kunye nemveliso yemizobo, ii-CNC ze-CNC Dlodes zidlala indima ebalulekileyo ekusika i-vinyl, ibhodi ye-foam, kunye nezinye izixhobo ezisetyenziselwa imiqondiso. Ukukwazi ukusika oonobumba, iimilo, kunye neelogo ezinemiphetho ecocekileyo kunye nendawo egudileyo iyenza ii-CNC ZEADS OKD OKWENZA IZAKHONO ZOKUFUNDA NOKUFUNDA. Isantya kunye nokuchaneka koomatshini be-CNC oxhotyisiweyo nge-Blades Clans Yenza abenzi boBeki ukuze bavelise iimveliso ezisemgangathweni ngokukhawuleza ngokukhawuleza nangokufanelekileyo.

Kwimizi-mveliso ye-agurospative kunye ne-aerospace imizi-mveliso, i-CNC Clodes isetyenziselwa ukusika irhasi, amatywina, kunye nezinto ezihlanganisiweyo ngokuchaneka kunye nokungaguquguquki. Amandla okufezekisa iiforances eziqinileyo kunye nemilo yentsusa ibalulekile kula macandelo, apho izixhobo zokusebenza eziphezulu kunye noyilo oluntsonkothileyo luqhelekile. Ii-CNC ze-CNC OneKhumbu zibonelela ngokuchaneka kunye nokuthembeka ezifunekayo ukuhlangabezana neemfuno ezingqongqo zezicelo ze-AutoMotive kunye ne-Aerospace, kuqinisekisa umgangatho kunye nokuthembeka kwiimveliso ezigqityiweyo.

Izinto ekufuneka ziqwalaselwe xa ukhetha i-cnc yokutyibilika

Xa ukhetha i-CNC ye-CNC YOKUGQIBELA YOKUGQIBELA, isicelo esithile kufuneka sithathelwe ingqalelo ukuqinisekisa ukusebenza kakuhle kunye nokusebenza kakuhle. Enye yeengcinga eziphambili kukusikwa, njengoko izixhobo ezahlukeneyo zifuna iintlobo ezithile ze blade kunye neparameter ezinqumlayo ukufezekisa ukusikeka okucocekileyo nokuchanekileyo. Izinto ezinzima ezinjengeentsimbi zinokufuna iintsimbi ze-carbide okanye ii-blayisi ezinamanyala okunqunyulwa, ngelixa izinto ezithambileyo ezinjengeenkuni zinokusikwa ngokufanelekileyo ngentsimbi yensimbi.

Enye into ebalulekileyo ekufuneka uyiqwalasele yisantya esisikiweyo kunye nexabiso londla, elichonge inqanaba apho ibala lihamba khona ngezinto. Ukulungelelanisa ezi parameter ngokweepropathi zezinto ezibonakalayo kunye nohlobo lwe-blade kubalulekile ekufezekiseni ukusika kunye nokucofa ngokuchanekileyo ngaphandle kokubangela umonakalo kwizinto okanye kwibala. Ukongeza, uyilo lweJometri yeJometri kunye ne-Edenes Dlala indima ebalulekileyo kwintsebenzo yokutyibilika, ukuphembelela izinto eziphathekayo ezinjenge-Chip, ukusika, kunye nokugqitywa komphezulu.

Uyilo lukhuselekileyo nolwakhiwo lwe-CCD Clade ichaphazela intsebenzo yalo kunye nobomi obude. Izinto ezifana nobungqingqwa, blade ikona, kwaye umgangatho wezinto ezibonakalayo unokuchaphazela ukuqina kwe blade kunye nokusika ukusebenza kakuhle. Ukukhetha i-blade ngendibaniselwano elungileyo yezi zinto kubalulekile ukwandisa imveliso kunye nokufezekisa iziphumo ezingaguqukiyo. Ngokuzihlola ngononophelo ezi zinto kwaye ukhethe i-CNC ibala le-CNC ehambelana neemfuno ezithile zeprojekthi, abavelisi banokuzixhasa iinkqubo zabo zokusikwa kwaye baphucule umgangatho wemveliso iyonke.

IINGXAKI ZOKUSETYENZISWA KOKUSETYENZISWA KWE-CNC Kokutsiba

Ukusetyenziswa kwe-CNC ye-CNC Dlodes ibonelela ngeenzuzo ezininzi kwiinkqubo zemveliso, ezenza zibe zizixhobo ezingenakuphikiswa ukuze zisike kunye nemisebenzi yokuxhasa. Enye yezibonelelo eziphambili ze-CNCK ye-CNCS kukukwazi kwabo ukuhambisa ngokuguqukayo kwaye zichanekile, kuqinisekisa ukufana kunye nomgangatho kwiimveliso ezigqityiweyo. Ulawulo oluchanekileyo olunikezwe ngoomatshini be-CNC luvumela abavelisi ukuba baphumeze uyilo oluntsonkothileyo kunye nemilo enzima ngokukhululekileyo, ukuphucula ubuhle beemveliso zokugqibela.

Elinye ithuba lokusebenzisa i-CNC LADS le-CNADS kukusebenza kakuhle kunye nemveliso abazizisayo kwimisebenzi yokuvelisa. Ngokuzenzekelayo imisebenzi yokusika kunye nokuphelisa iimpazamo zencwadi, oomatshini be-CNC axhotywe ngamabala e-Knuel banokunciphisa kakhulu ixesha lokuvelisa kunye neendleko ngelixa benyusa imiqulu yegalelo. Isantya esiphezulu sokusika kunye nokuchaneka kwe-CNC KUNIFIX Blades ukwenza ukuba abavelisi beenkqubo zabo kwaye bahlangabezane nemihla yokuvelisa eqinileyo ngaphandle kokulalanisa kumgangatho.

Ngaphaya koko, ii-CNC Kimen Blades zibonelela ngokuqatha ekunciphiseni uluhlu olubanzi lwezixhobo, ukusuka kwi-sotwood kunye neeplanga kunye nezinyithi. Oku kusebenza kuqondakalisa kuvumela abavelisi ukuba baphathe iiprojekthi ezahlukeneyo kunye nezixhobo ngesixhobo esinye, ukunciphisa isidingo semisebenzi emininzi yokusika kunye nokwenza iNdawo yokuFumaneka kweMveliso. Nokuba ngaba iipateni ezintsonkothileyo kwilungu le-acrylic okanye ezinciphise ii-brade zentsimbi, ii-CNC ze-CNC zibonelela ngokuguquguquka kunye nokuziqhelanisa nokuzonwabisa ngokufanelekileyo ukujongana nemiceli mngeni emininzi yokusika ngokufanelekileyo.

Yiyo yonke le nqaku. Ukuba uyayifuna le ntoI-CNC KAKHUMILokanye unemibuzo malunga nayo, unganxibelelana nathi ngokuthe ngqo.

Emva kwexesha, siya kuqhubeka nokuhlaziya ulwazi, kwaye unokufumana ulwazi ngakumbi kwiwebhusayithi yethu (i-Palverntool.com) blog.

Ewe kunjalo, unokunikela ingqalelo kwimidiya yethu yaseburhulumenteni:

I-Post Time: Aug-28-2024